Ok, so this is basically what you have to know to be able to conduct a Factory Acceptance Test for the control panel.

Hence, over the execution in the Factory Acceptance Testing, It is crucial which the project leader or even the operator with the devices being tested, are existing. At times It is necessary that a third party is usually present, like the designer in the equipment.

The maker is answerable for rectifying the issues and retesting the gear right up until it comply with the necessities spoken in the checklist.

For example, Allow’s mention that that is a strain transmitter that may be used to evaluate the oil pressure in the process. Depending on the PLC logic, When the oil tension goes less than a specific degree the oil pump should turn on.

High quality supervisor inside the factory asset can customise this print depending on the specs on the equipment to go through a firm acceptance test.

eleven. Know the distinction between a Factory and Web-site Acceptance Test. One of the most significant parts of confusion bordering the Fats is in excess of whether or not it need to simulate how the device responds beneath real factory ailments. In truth, that may be the objective of the Site Acceptance Test (SAT). In the machinery builder’s plant, it could be hard or maybe impossible to simulate the two the output volume as well as the conditions of your product, specifically for more than a few minutes.

The manufacturing staff need to be included early on in the procedure is among the most critical aspects of designing new gear.

If the devices’s specification is not really based on the manufacturer’s prerequisites, the Unwanted fat is said for being unsuccessful. The equipment’s maker is accountable for eradicating the deviation.

The cookie is set through the GDPR Cookie website Consent plugin which is accustomed to shop whether or not person has consented to using cookies. It does not keep any individual data.

Device Acceptance Form This equipment acceptance form can be used to complete the process validation protocol by reporting and verification with the machines’s possibly procedure’s ultimate design against the consumer, purposeful, and/or layout specification.

Don’t shy faraway from testing essential critical possibility areas like communication interfaces, velocity or Model one.0 of latest program (which you ideally determined as vital regions inside your chance assessment).

Unwanted fat presents operators a chance to functionally test a bit of apparatus just before it leaves the store, supplying Every person an opportunity check here to go over concerns and modifications.

With out acquiring the crew on-site, distant FATs current an increased chance for equipment being transported devoid of meeting the tip person’s demands and purposeful specifications.

Machine Acceptance Type This appliance acceptance sort may be used to finish the procedure validation protocol by reporting aforementioned verification of your equipment’s or technique’s last design and style against the entire, operate, and/or style and design technological innovation.

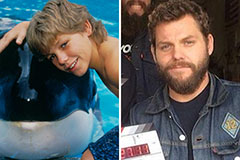

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!